Integrated Automation for Rubber Seal Manufacturing

Table of Contents

Integrated Automation for Rubber Seal Manufacturing #

SCPT Machinery delivers fully integrated production systems for rubber sealing applications, with a focus on oil seals, rubber-metal bonded parts, and precision sealing rings. Our approach combines advanced technology, innovative design, and a commitment to quality, enabling manufacturers to achieve high efficiency, consistent product standards, and compatibility with smart factory environments.

Our Approach to Rubber Seal Production #

We are dedicated to providing efficient and reliable equipment for rubber seal manufacturing. By leveraging a professional design team and ongoing technological innovation, our solutions help customers enhance productivity, reduce operational costs, and maintain stringent quality standards.

Key Features #

-

Innovative Design & Advanced Technology

Our team continuously develops and integrates cutting-edge technologies, ensuring that our equipment remains at the forefront of the industry. These advancements not only boost equipment performance but also support customers in reaching higher production targets. -

Strict Quality Control & Testing

Every piece of rubber seal production equipment undergoes rigorous quality control and testing. This ensures stable operation across diverse production environments, minimizes production risks, and reduces maintenance costs, ultimately delivering greater value to our clients. -

Comprehensive Support & Services

We offer a full spectrum of support and services, with a technical team ready to address questions and provide tailored solutions. Our attentive service has earned widespread recognition from customers.

Oil Seal Production Process Overview #

The production of oil seals involves several key stages, each supported by specialized equipment:

-

Oil Seal Iron Case Treatment

- Manual or automatic feeding and beveling

- Large oil seal iron case forming and beveling

- Combining treatment

- Oil seal film treatment

- Explore Iron Case Treatment Machines

-

Rubber Cutting

- Adjustable rubber string cutting machines

- Fixed type and servo motor type rubber slicing machines

- Explore Rubber Cutting Machines

-

Seal Molding & Vulcanization

- Vacuum and column type rubber vulcanizing machines

- Explore Vulcanizing Machines

-

Automatic Deburring of Rubber

-

Burr Trimming / Deflash

- Manual or automatic feeding

- Suitable for large oil seals, PU packing, and cups

- Explore Trimming Machines

-

Slice-Ring Cutting

- Machines with one, two, or four cutting shafts

- Options for automatic feeding and discharging

- Explore Slitting Machines

-

Spring Loading

- Oil seal and valve steam seal spring loading machines

- Explore Spring Loading Machines

-

Dimension Inspection

- Manual and automatic feeding options

- Explore Dimension Inspection Machines

-

Grease Filling

- Manual and automatic feeding options

- Explore Grease Filling Machines

-

Seal Testing Equipment

- Durability lifecycle testing

- Rotation durability testing

- Lips tensile strength and torque testing

- Explore Testing Machines

-

Other Specialized Equipment

- Oil seal cutter grinding (dry/wet)

- Explore Cutter Grinding Machines

- Auto silicone dispensing

- Explore Silicone Dispensing Machines

Equipment Gallery #

Thermoforming Equipment

Thermoforming Equipment

Oil Seals Trimming Machine

Oil Seals Trimming Machine

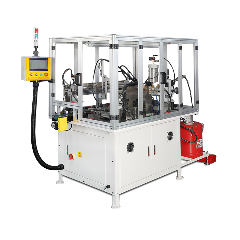

Auto Multi-Functional Oil Seal Working Line

Auto Multi-Functional Oil Seal Working Line

Oil Seal Iron Case Treatment Series

Oil Seal Iron Case Treatment Series

Oil Seal Spring Loading Machine Series

Oil Seal Spring Loading Machine Series

Oil Seal Grease Filling Machine Series

Oil Seal Grease Filling Machine Series

Oil Seal Cutter Grinding Machine

Oil Seal Cutter Grinding Machine

Oil Seals Dimension Inspection Machine

Oil Seals Dimension Inspection Machine

Oil Seal Testing Machine

Oil Seal Testing Machine

Rubber Injection Machine

Rubber Injection Machine

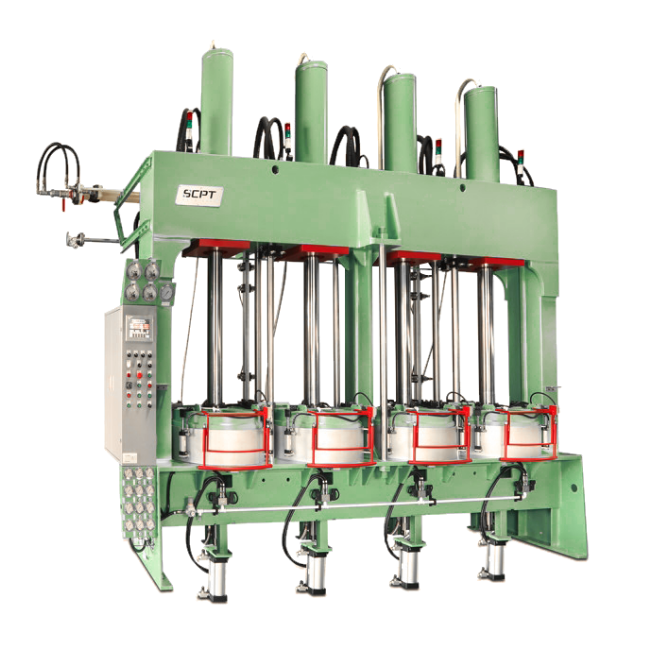

Rubber Vulcanizing Machine

Rubber Vulcanizing Machine

Rubber Molding Machine

Rubber Molding Machine

Tire Curing Press Machine

Tire Curing Press Machine

Rubber String & Slicing Machine

Rubber String & Slicing Machine

How We Support Your Production Goals #

If you have questions or require assistance, our team is ready to provide expert support and solutions tailored to your specific needs. Contact us to discuss how we can help you achieve your manufacturing objectives.